Product Prototype Development

Product Prototypes are a critical tool after design and engineering stage that we use in all of our projects. Prototypes are not just a final project milestone, but are actually used for many specific things within the product development project:

Feature Set Validation

Successful product prototype development hinges upon a thorough understanding of what feature set are the right one for your product. By taking a smart approach to product prototype making, feature sets can be tested and validated, reducing risk in later development work. We apply lean principles to the prototyping process, which makes the most of your development budget.

Functional Validation

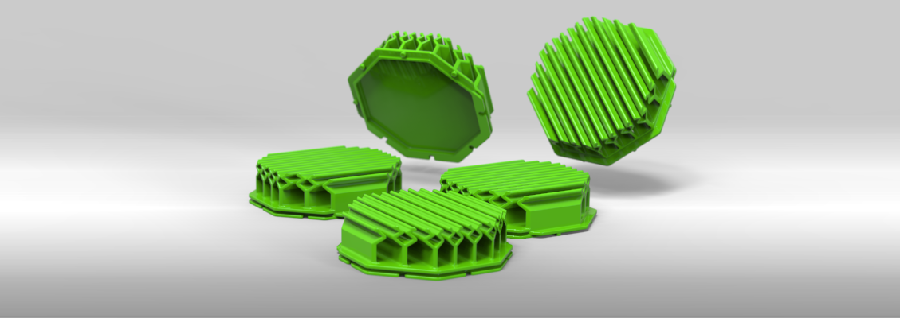

Nearly all of our projects include functional product prototypes as development tools. Once the proper feature set is identified, functional prototypes serve to determine if the design approach provides the function to deliver the feature. We create prototypes using our in-house electronics lab, in-house Stratasys 3D Printer, as well as outside vendors for specific components.

Manufacturing Validation

Great design is not enough. Products must also be compatible with manufacturing processes and cost targets. Physical product prototypes in addition to virtual models serve to communicate intent to the manufacturer and open a discussion about final design changes for production.

Minimum Viable Product

A disciplined approach to product prototyping includes only the design and engineering elements that are critical to test or validate at that point in time. Product prototypes are learning tools – prototype development companies will include things needed to answer feasibility, ergonomics, user experience questions – and much more. Our prototyping approach is in line with methods defined in The Lean Startup which helps customers and especially new company to save budgets.

A Guide To Prototypes: 4 Levels

There are multiple approaches to prototyping and the right prototype plan depends on the product, the development risks, and the business goals of the client. In general, a prototype is used to learn something. This can range from learning whether a mechanism is feasible to whether a feature set is meaningful to the market. Different levels of a prototype are appropriate at different stages of development. We have built this guide to help explain the prototype levels, and how they relate to each other.

Prototypes can be categorized into four levels. For each level, the prototype gains features and fidelity. Level 1 prototypes may only be a subsystem or mechanism where Level 4 prototypes are as close to the final product as possible. It is typical to go through multiple iterations, with multiple prototypes within each level.

Level1: Feasibility Prototype

The Feasibility Prototype is not usually what comes to mind when many people think about prototyping. However, this level of a prototype is extremely important as it can be used to validate individual features for feasibility. If it turns out a feature must be reworked in order to be achieved, level 1 prototypes can be iterated until it is completely debugged. Alternatively, this stage can help developers decide if a feature is worth keeping on a product based on technical feasibility. Level 1 prototypes often do not incorporate much consideration for aesthetics, but focus more on testing possible configurations for functionality. At this early stage of development, product and feature set pivots are far less costly than they are in late stage development. This is why it is common to develop multiple level 1 prototypes in parallel, to compare the merits of different design approaches.

Level 2- Preliminary Product Prototype

The Preliminary Product Prototype is where components begin to come together and the product starts to take shape as a functional device. Components at this stage are still in an experimental phase. In some cases, only some features will be built into the prototype and the body of the product may only be a shell to use as a reference for the final product. Likewise, with electronics design, the Preliminary Prototype phase is when circuitry begins to make its way from prototyping and breadboards to printed circuit boards and starts to get connected to hardware. This stage can provide a lot of insight into how components will work together as well as identify any possible limitations or shortcomings in the design. For many business owners, this is the point where they can start to see their idea take shape (literally) and begin to understand from an engineering perspective and get a real tangible understanding of possible areas of improvement and expansion as well as see and understand design limitations. Prototypes at this stage often use different materials than the final product for the sake of rapid manufacturing. The final product may have an aluminum body, but the prototype could be printed from ABS plastic.

Level 3: Demonstration Prototype

The Demonstration Prototype may include many of the features and functions of the final product. This prototype is at the stage where it can begin undergoing user testing. This prototype is also meant to start demonstrating the aesthetic components of a product and begin testing the appearance. Sometimes this means building with multiple different materials to reach the desired look and feel. However, this stage or prototype may not look exactly like the final product. This level of prototyping may change significantly in later iterations depending on the needs of the client and the needs of manufacturers. For many companies, this is the stage of a prototype that is used for showing off to potential investors, developing marketing and sales materials, and for submission to crowdfunding platforms such as Kickstarter. The challenge with services like Kickstarter is often they require a product be developed to a certain extent before companies can start a campaign. This prototype is often the showpiece for these campaigns since it demonstrates a level of completed work that satisfies the Kickstarter requirements. The Demonstration Prototype is meant to actualize the final vision of the product, even if not all features are included.

Level 4: Pre-Production Prototype

The Final Pre-Production Prototype is essentially a one-off version of the final product, using prototype materials. While visually it may appear similar to a level 3 prototype, it has a fully functional and complete feature set, and it looks great but has typically not been optimized for manufacturing. Although it may seem like the product is complete, this level of prototype provides a critical opportunity to field test and analyze the final product before investing in tooling. Additionally, this is a final chance to address any last issues that may need to be worked on. This is the last step before a product’s design is sent to the manufacturer to be produced and ultimately packed and shipped to customers. Getting to this level of a prototype can mean multiple passes at earlier levels, a product may stay in level 4 a long time before it is ready to be made into a final prototype. Some of the final steps in moving a Level 4 prototype forward are to get the parts optimized for manufacturing. Whether that means making adjustments for injection molds or adjusting the location of components, this stage allows engineers to learn what compromises must be made to make the final product successful for mass-production. Even if a product will not be manufactured for mass consumption, low volume products need to be optimized for manufacturing. Although manufacturing should be in the mind of the designers at every stage of the product’s development, this is the stage where the learning is more focused on industry requirements and the focus shifts from user feedback, to manufacturer feedback.